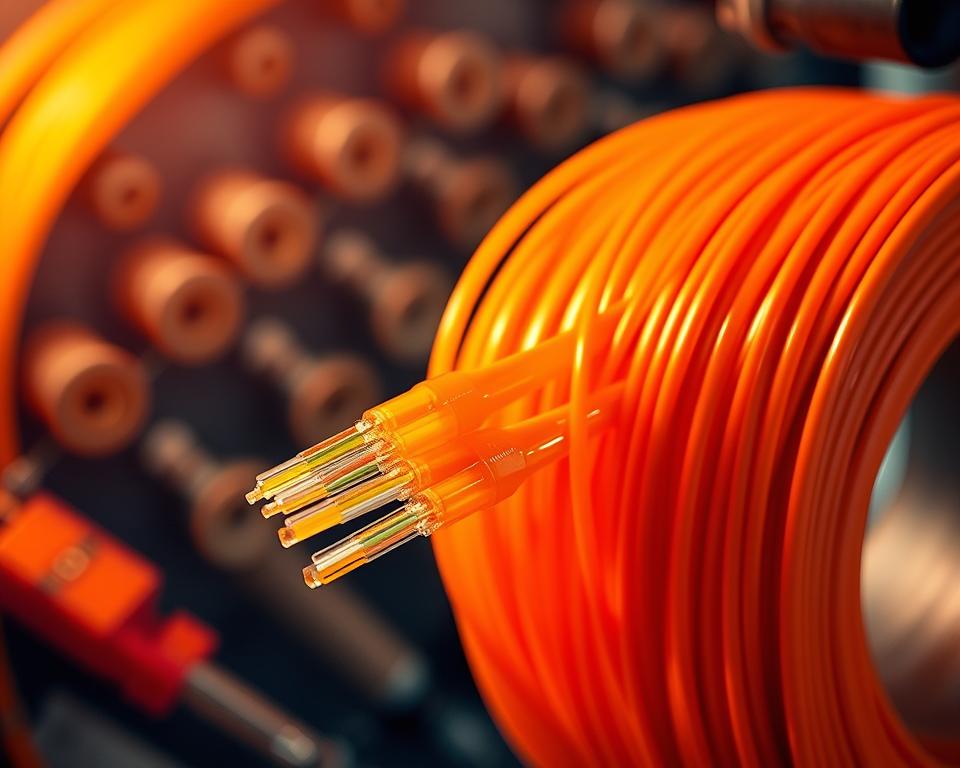

FTTH Cable Production Line – State-of-the-art Production System

Were you aware that up-to-date fiber optic cabling setups are capable of running at rates of up to 190 m per minute? This incredible efficiency is made possible by innovative fabrication techniques tailored to swift manufacturing.

These configurations are built to manage multiple cabling forms, such as drop cables and compact buffered wires. Their efficient construction, typically below 26 m, suits them well for state-of-the-art factories.

Incorporation into smart factory systems guarantees uninterrupted performance. Via MES/ERP connectivity, these compact fiber unit assembly lines offer unmatched accuracy and productivity. This renders them the leading option for companies aiming to stay ahead in the fiber network field.

FTTH Cable Fabrication System Introduction

Productive manufacturing setups are key to addressing the increasing requirement for steadfast connections. These configurations are engineered to produce top-grade fiber optic cables that drive modern networks. By leveraging modern innovations, they ensure exactness and rapidity in all phases of the process.

Understanding the FTTH Manufacturing Line

An FTTH production line is an integrated system for manufacturing fiber-to-the-home drop cables. They include bare fibers reinforced with iron or FRP materials, merging with safeguard coverings. This produces a long-lasting and high-performance option for high-speed internet connections.

The system is compatible with diverse substances, such as PVC, LSZH, and PE plastics. This versatility confirms it can meet diverse industry needs. Additionally, the four-head fiber discharge system delivers exact tension management, keeping stability within ±0.05N.

Reasons to Select Our Cutting-edge Production System

Our machinery excels for its precision and efficiency. Consider these highlights:

- Accommodates diverse cable formats like 2.0×3.0mm and 2.0×5.0mm drop cables

- Supports LSZH, PVC, and PE sheath materials for versatile applications

- Boasts a quad-head payout mechanism controlling tension between 0.4N and 1.5N

- Achieves speeds reaching 9km/h for 2.0×3.0mm cable outputs

With these features, our machine ensures smooth operations and high-quality output. Thus, it becomes the optimal option for enterprises aiming to stay ahead in the fiber optic industry.

Key Features of Our FTTH Cable Production Line

State-of-the-art fabrication lines are transforming how optical fibers are manufactured. Our advanced equipment merges exactness, performance, and modern advancements to yield superior outputs. The following outlines the remarkable components that position our system at the forefront.

Precision Extruder and Adjustment Head

At the heart of our system is a specialized 50mm extruder designed for precise material distribution. This ensures uniform excellence across every fiber cable produced. The modifiable head supports smooth personalization, accommodating different substances like PVC, LSZH, and PE polymers.

Equipped with OMRON heat management, the system ensures temperature exactness to ±1°C. This level of precision guarantees optimal performance and reduces waste, rendering it an economical choice for production.

Motorized Fiber Release and Tension Control

Our motorized fiber release system is engineered to maintain tension between 0.4N and 1.2N. Such regulation facilitates flawless fiber manipulation and diminishes breakage risks. The dual-wheel capstan system, with diameters of 640mm and 400mm, further enhances stability and control.

This feature is particularly beneficial for producing high-quality fiber cables, by maintaining uniform strain during production.

Automated Take-Up and Line-Receiving System

Our dual-shaft take-up system supports reels ranging from PN400 to PN630, offering flexibility for various production needs. The automated line-receiving feature eliminates the need for manual rewinding, thereby cutting processing time and minimizing workforce expense.

Additionally, the X-type laser diameter gauge provides real-time quality control, confirming that each optical cable adheres to rigorous benchmarks, resulting in trustworthy and long-lasting outputs.

State-of-the-art Technology Powering the Production Process

Modern innovations are revolutionizing the production of fiber optic cables. These setups are crafted for accuracy, dependability, and high performance, guaranteeing superior outputs in every production run. Below, we explore the advanced features that set our equipment apart.

International Industrial Computer Control System

Central to our operation lies the FiberCAN PLC coupled with an industrial-grade PC interface. This technology ensures seamless operations and real-time monitoring. It permits meticulous modifications, which improve the standard of every optical fiber made.

With energy use as low as 35KW/h during routine activity, our equipment is energy-efficient. This conserves energy costs without compromising on output quality. A 9-meter cable accumulator supports continuous operation, cutting delays and boosting throughput.

Outstanding Durability and Dependability Using Renowned Parts

The assembly includes high-grade parts sourced from famous companies such as OMRON and global motor manufacturers selected due to their robustness and accuracy, promising lasting dependability.

Steel-reinforced wiring combined with sophisticated Fiber cable sheathing line management systems bolsters robustness and balance, ensuring that every optical cable meets industry standards for quality and performance.

MES/ERP Connectivity Integration

Our equipment integrates seamlessly with MES and ERP systems, enabling real-time production tracking. It provides complete visibility and operational efficiency across all stages.

With this integration, businesses can monitor production metrics, optimize workflows, and reduce waste, rendering it a savvy option for today’s industrial plants.

| Feature | Upside |

|---|---|

| FiberCAN PLC Setup | Exact tuning with live oversight |

| 35KW/h Power Consumption | Cost-effective power usage |

| Nine-meter Cable Storage | Seamless operation |

| OMRON Controllers | Long-lasting accuracy |

| ERP Connectivity | Real-time production tracking |

Practical Applications for Our FTTH Cable Line

Advanced production setups are revolutionizing the production of dependable fiber networks. They cater to a broad range of industrial demands, ensuring adaptability and accuracy across usages. The following outlines the primary applications of this state-of-the-art system.

Producing FTTH Drop Cables

This production line is outstanding at creating drop cables vital for rapid internet connectivity. It handles reinforcement wires ranging from ø0.4 to ø1.0, ensuring durability and strength. The central shaft hole diameter of ø56 allows for seamless integration with PN400 pay-off reels.

Notable attributes are:

- FRP and small steel wire pay-off for added reinforcement

- Portable die backing for rapid setup modifications

- Adaptability to meet interior as well as exterior standards

Manufacturing Tight Buffered and Loose Tube Cables

The system is also ideal for producing tight buffered and loose tube cables. Boasting a minimal attenuation of only 0.02dB/km, these cables perform remarkably well. The stranding process ensures precision, while the ability to handle ø1.2mm steel wires adds strength and reliability.

Adaptable Manufacturing for Different Cable Varieties

Adaptability is a defining feature of our production line. It is compatible with an array of materials and setups, thus fitting multiple applications. Be it for interior or exterior wiring, our machinery provides uniform excellence and productivity. This adaptability ensures that businesses can meet specific requirements without compromising on performance.

Benefits of Using Our FTTH Cable Production Line

Investing in advanced manufacturing systems yields numerous benefits to fiber optic businesses. These systems are designed to optimize operations, reduce costs, and deliver high-quality products. Here are the principal merits that render our equipment indispensable for today’s production facilities.

Enhanced Efficiency and Productivity

It guarantees rapid Fiber draw tower function, producing 7-9km/h outputs based on cable dimensions, permitting enterprises to fulfill increased market needs while sustaining superior quality. Additionally, automated spool handling diminishes labor effort, enhancing time efficiency and resource use.

Economical Fiber Optic System Implementation

Operating at a reduced 35KW/h, our machinery significantly cuts running costs. The ergonomic design, featuring a 1000mm working height, enhances operator comfort and efficiency.

Polished and Dependable Cable Exteriors

Accurate extrusion guarantees an even and trustworthy finish on each cable, thereby reducing attenuation to ≤0.02dB/km for peak performance. Incorporating steel reinforcement further solidifies the cables, adapting them to diverse applications.

| Characteristic | Benefit |

|---|---|

| High-Speed Production | Increased operational efficiency |

| Low Energy Requirement | Lower energy costs |

| Negligible Attenuation | Enhanced signal quality |

| 1000mm Working Height | User-friendly setup |

Conclusion

Cutting-edge optical cable manufacturing is establishing fresh industry norms. With precision engineering and smart integration, these machines deliver unmatched reliability and efficiency. Their high-speed capabilities, reaching up to 190 meters per minute, ensure a strong return on investment for businesses.

With robust support services and versatile customization capabilities, our equipment adapts to particular demands. Be it expanding production or boosting quality standards, our system is crafted to keep you at the forefront.

Prepared to revolutionize your production line? Reach out now to discover customized options that match your needs. Experience the future of fiber optic technology with our industry-leading systems.